Did you know...

UN accreditation

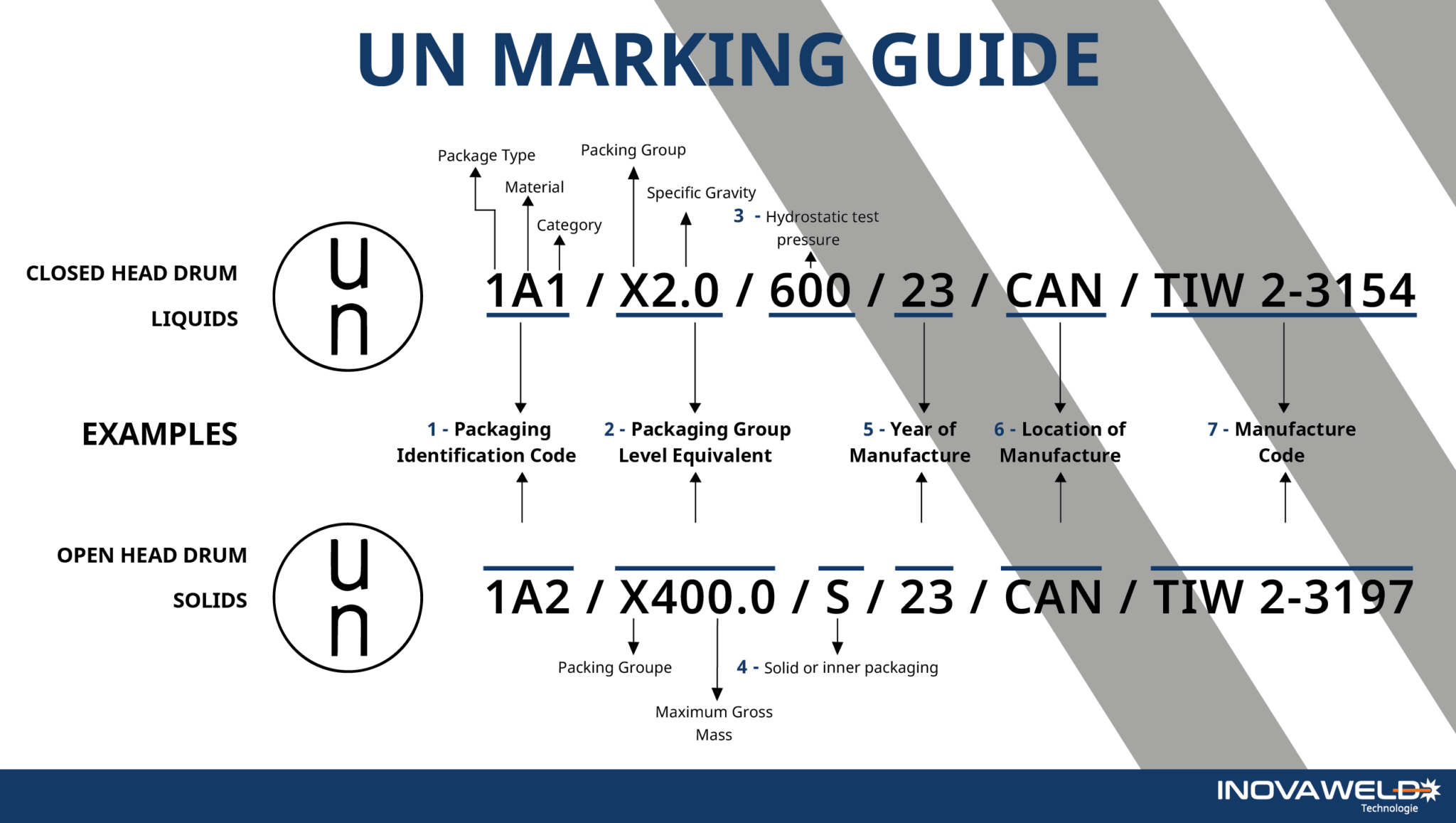

The codes

UN classifications appear on industrial packaging as a long series of letters, numbers and symbols. This marking is permanent and the UN classification explains what materials or substances the barrel is certified to transport. For an industrial storage barrel, for example, the classifications refer to the following:

Packaging identification code

Package Type

1 – Drums/pails

2 – Barrels

3 – Jerricans

4 – Boxes

5 – Bags

6 – Composite packaging

7 – Pressure Receptical

Material

A – Steel

B – Aluminium

C – Natural Wood

D – Plywood

E – Reconstitued Wood

F – Fiberboard

Category

For Drums

1 – Closed Head

2 – Open Head

Packaging Group Level Equivalent

Specific Gravity vs Maximum Gross Mass

Gross Mass for Solids – The mark will include the maximum gross mass (kilograms) that the package can weigh when filled (packaging plus its contents).

Specific Gravity for Liquids – The mark will contain the maximum specific gravity allowable for that packaging.

Packaging Group

X = Packing Group I (Highest Degree of Danger)

Y = Packing Group II (Medium Degree of Danger)

Z = Packing Group III (Lowest Degree of Danger)

Solid Packaging

Solids – If intended to contain solids or combination packagings for all materials, the mark will include a capital “S”.

Hydrostatic Pressure

Liquids – For liquid hazardous materials in single or composite packagings, the mark will contain the hydrostatic pressure the container was tested to; the hydrostatic pressure should be included in kPa (kilopascals) rounded down to the nearest 10 kPa.

Year of manufacture

The marking must indicate the last two digits of the year of manufacture.

Location of manufacture

The symbol of the country where the manufacturing took place must be listed in the mark. CAN stands for CANADA.

Manufacture code

The identification of the party who is certifying that the packaging meets all of the required testing must be included in the mark. TIW stands for Technologie Inovaweld’s registration code.

UN accreditation

The tests carried out

To obtain UN certification, each product must pass very rigorous testing. Here are some basic tests:

Drop test

This test involves dropping a barrel in free fall from all sides (top, bottom, side, corner, etc.). All deformations and leaks are noted.

Stacking Test

This test consists of determining the compressive strength of a barrel under constant weight for a period of time.

Pressure test

This test determines the maximum internal pressure that the barrel can experience. The barrel is filled with water to capacity and maintains constant pressure for few minutes.