Did you know...

Stainless steel

Stainless steel is a ferrous metal alloy, the main characteristic of which is resistance to corrosion. In addition to its main characteristic, stainless steel has an aesthetic, resistant, healthy structure with easy maintenance. All of its characteristics make this type of steel an essential element in several sectors of activity such as: building, medicine, shipbuilding, aeronautics, automotive, cooking, mechanics, chemicals, ‘agrifood, transport, etc.

In addition to the many advantages that stainless steel offers, it can also be completely recycled. This steel is one of the “greenest” materials in the industry because it can be recycled over and over again. We can list the following advantages :

- Has strong resistance to impact, failure, weathering, degradation and corrosion.

- Soft; easy assembly and connection.

- Strong resistance to high temperatures and thermal shocks.

- Its solid, waterproof outer structure prevents ingress of food and restricts the adhesion of biofilms.

- Does not infect food and does not change the smell and taste (organoleptic properties) of the latter.

- Presents a beautiful appearance or external structure.

brief history

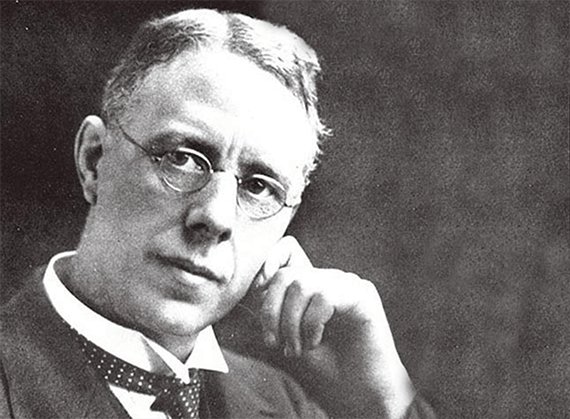

In 1913, during his studies aimed at reducing the corrosion of gun barrels, Harry Brearley of Brown-Firth Laboratories (UK) invented a type of steel which he called “rust-free steel.” “. It was then that he discovered that chromium added additional resistance to rust to the alloy. It was only later that this alloy was renamed “stainless” (spotless, or pure).

From 1924, William Herbert Hatfield replaced Harry Brearley in his post at the head of Brown-Firth Laboratories. He developed the “18/8” steel, (18% by mass of Chromium and 8% by mass of Nickel) which is certainly the extra that is used the most among iron-nickel-chromium steels.

British inventor Harry Brearley, created the first type of stainless steel material in 1913. Credit: Wikimedia

Composition

Stainless steel is an assembly containing more than 50% Iron, a minimum of 10.5% of Chromium and a maximum of 1.2% of Carbon.

It also contains Nickel, Molybdenum, Titanium, etc.

There are many different kinds of stainless steel today (different combinations), because not having the same characteristics they will behave differently in a given environment. So there is no good or bad stainless steel. Depending on the need, one can opt for a malleable steel, stronger or even more resistant to corrosion.

A chromium content of more than 10.5% in the alloy generates a protective layer of chromium oxide which thus renders the product stainless.

Nickel reduces corrosion by optimizing the characteristics of the passive layer. Also, it generally improves the mechanical characteristics and more particularly the malleability. It should be noted that Nickel is a gammagenic metal, which offers an austenitic structure and offers the possibility of obtaining easily malleable sheets.

As for Carbon, a high rate allows the steel to be quenched and gives a very solid finish. However, it weakens the weldability of the alloy and can hamper the placement of the passive layer.

Wikipedia. (2021, dec 13). Stainless steel. Récupéré sur Wikipedia, The Free Encyclopedia: https://en.wikipedia.org/wiki/Stainless_steel

The main categories of stainless steels

Austenitic (304, 316)

This family of stainless steel has great resistance to corrosion, is very malleable and offers great weldability. This category is generally made up of the ratio (18/8) (18% by mass of Chromium and 8% of Nickel). This type of stainless steel is useful in the food industry, in the kitchenware manufacturing industries, in chemical reactors, in architecture, in jewelry, in the medical sector, etc.

Ferritic (409, 430, 446)

This stainless steel family is resistant to corrosion and does not offer great weldability. However, it is much more economical. This type of stainless steel is useful in the manufacturing industries of automotive exhaust systems, industrial parts, household appliances.

Martensitic (410, 420, 440)

This family of stainless steel has low corrosion resistance and inferior weldability. However, this type of stainless steel is very wear resistant, very durable and can be tempered. It is generally used for reactors, valves, burners and cutlery.

Duplex (2304, 2205, 2507)

Cette famille d’acier inox offre plus souvent des propriétés mécaniques supérieures et présente une plus grande résistance à la corrosion que les aciers ordinaires tels que les austénitiques et les ferriques. On l’utilise généralement pour les plateformes pétrolières, les industries chimiques, etc.

Eagle Stainless Tube & Fabrication. (2021). Stainless steel characteristics. Récupéré sur Eagles Stainless : https://eagletube.com/about-us/news/stainless-steel-characteristics/

Fun facts

- Stainless steel does not undergo any cold corrosion except for moisture. It has the ability to withstand very corrosive gases like chlorine as long as it is really dry.

- “The use of magnets for verification tests is not really true, because different kinds of stainless steels can be attracted to a magnet.

- If a stainless steel barrel gets scratched by a steel object, the scratched part may be corroded because it will be infected by the steel.

- For you, it is clear that stainless steel can be completely recycled. But did you know that it is one of the most recycled materials in the world?